Virtuous supply chain

Plastisac develops virtuos supply chains in waste management to obtain the raw material necessary to produce new packaging. In fact we take all our processing waste to regeneration, obtaining new raw material, thus eliminating waste. Regenerated raw materials maintain excellent technical characteristics and are not only used in the food and biomedical sectors.

In recent years, we have been committed to reducing CO2 emissions by agreeing with the Ministry of the Environment (The Kyoto Protocol). As well as other initiatives strictly connected to environmental issues, the company's management increasingly move towards environmental sustainability in production choices and manufacturing methods.

For this reason, we decided to define, in partnership with our customers, the possibility of developing virtuous supply chain in waste management from which we obtain the raw material necessary for the development of new packaging. A circular economy lays the foundations in reducing emissions from production processes and optimises all stages of the supply chain.

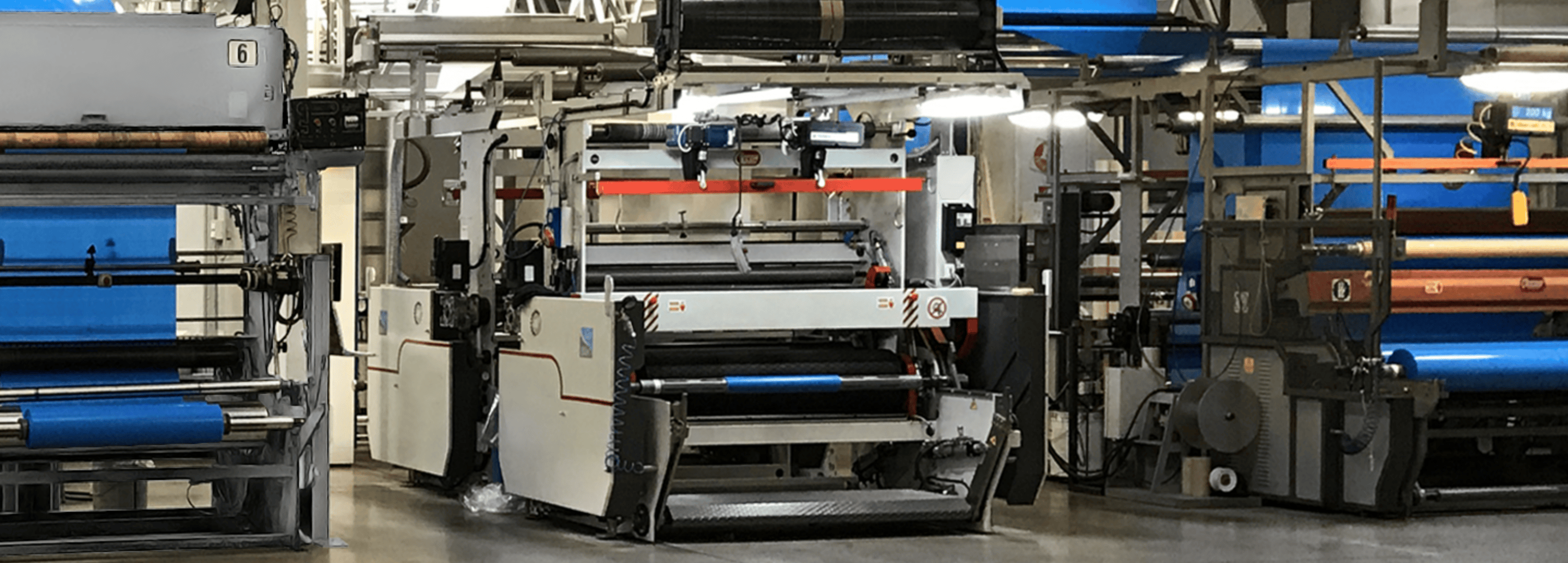

At the processing stage, we have innovated our technologies to ensure the manufacture of environmentally friendly polyethylene products.

+39 0376 391192

+39 0376 391192